Filter Plates

We are committed to meeting the diverse needs of our customers and providing them with suitable solutions. As innovative experts in solid-liquid separation, we have a comprehensive product range that can be customized to our customers' requirements. Therefore, each of our product types can be tailored to meet your customers' needs.

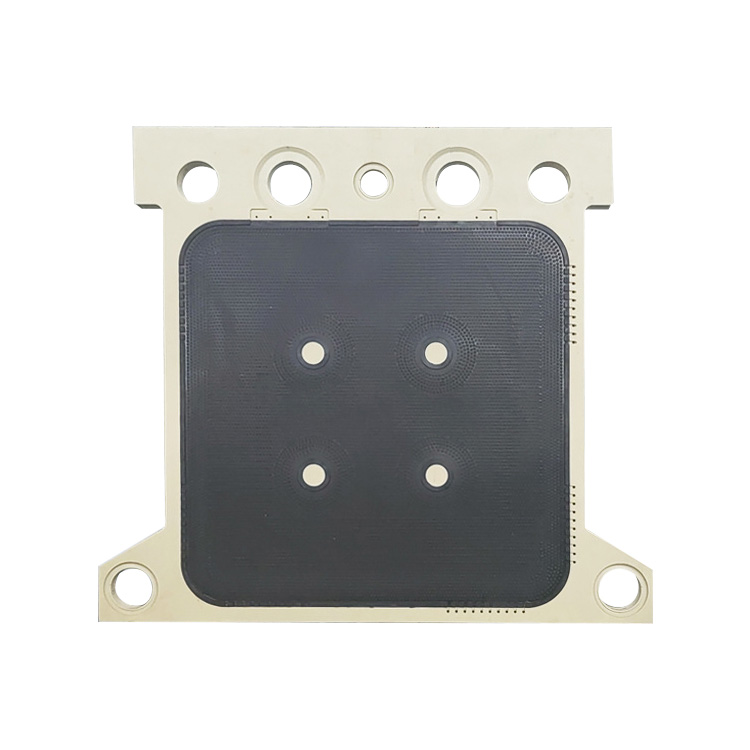

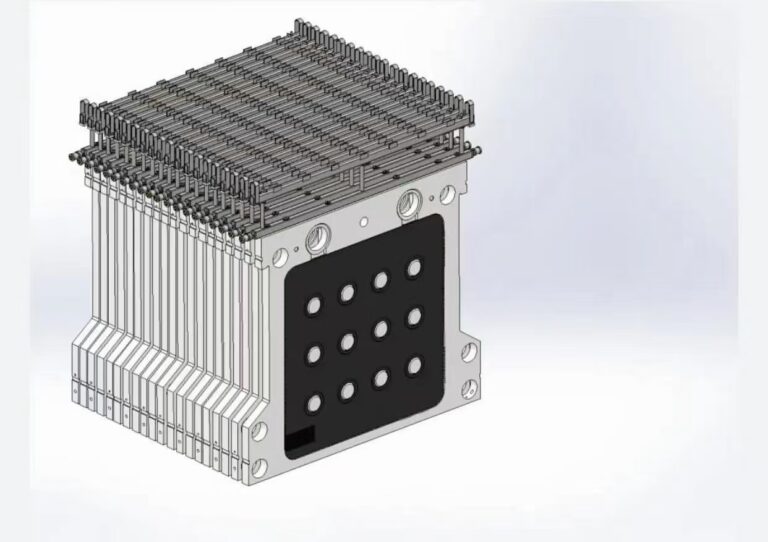

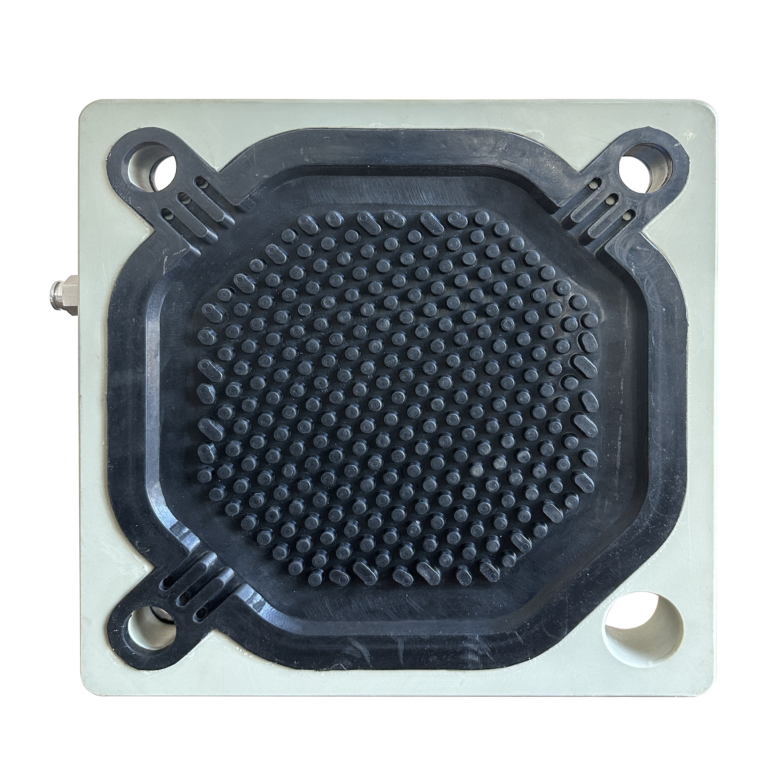

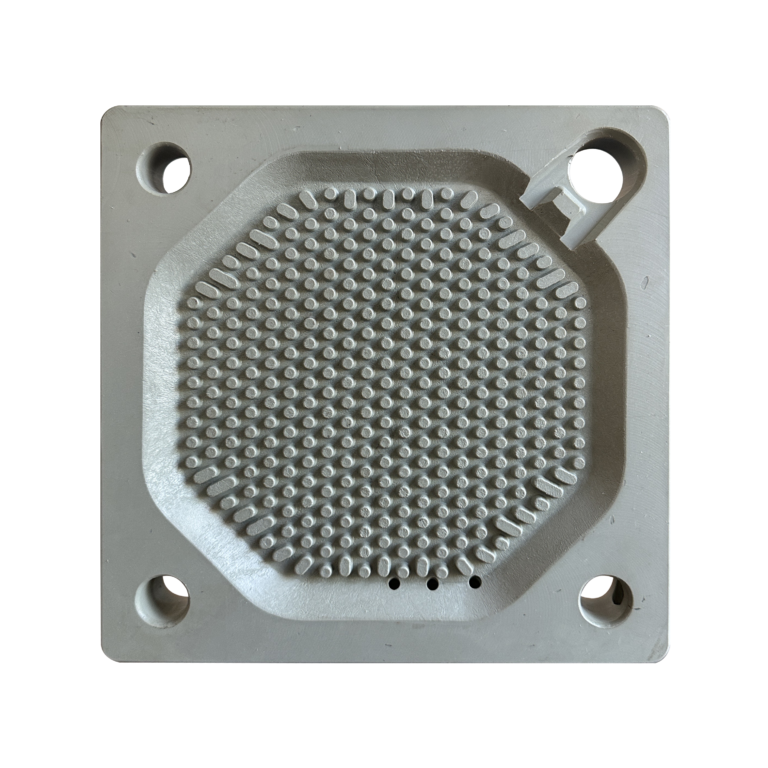

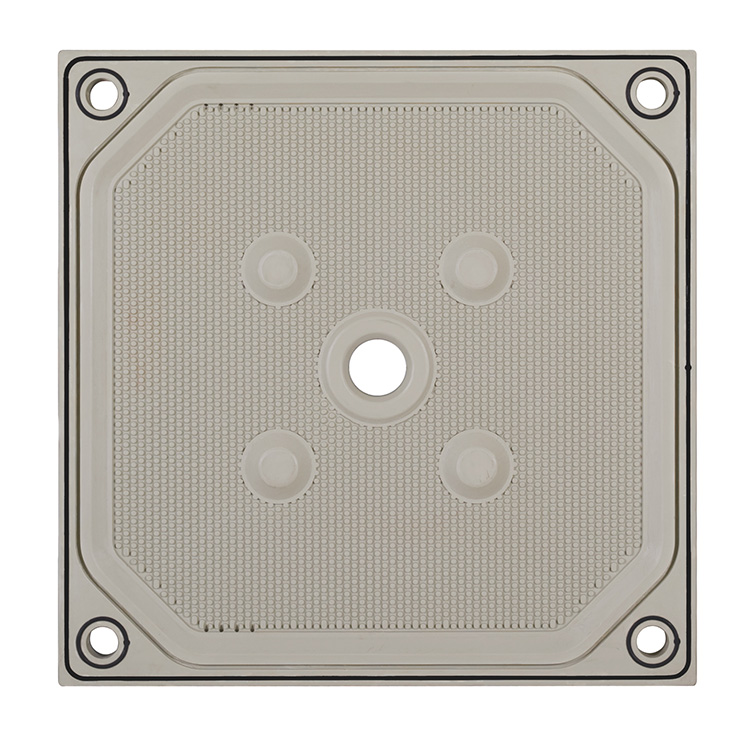

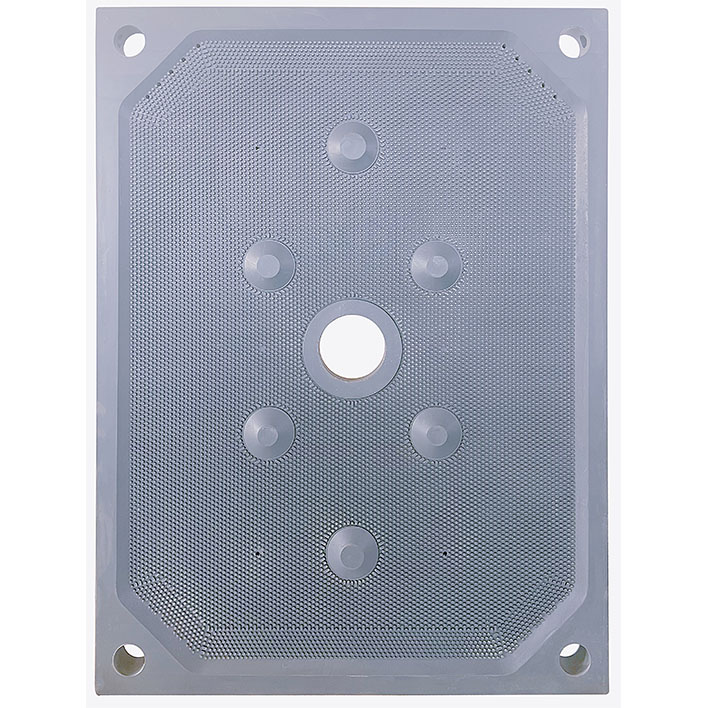

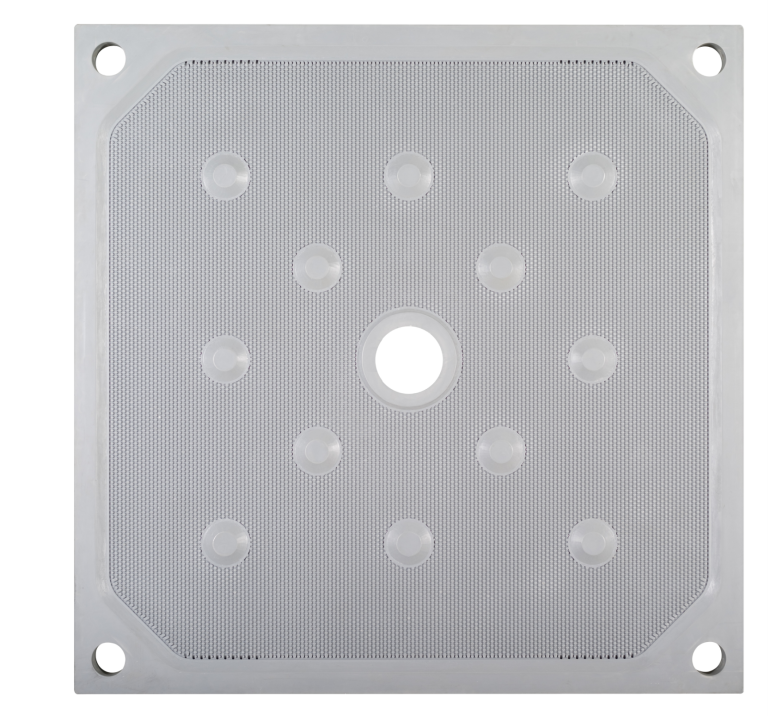

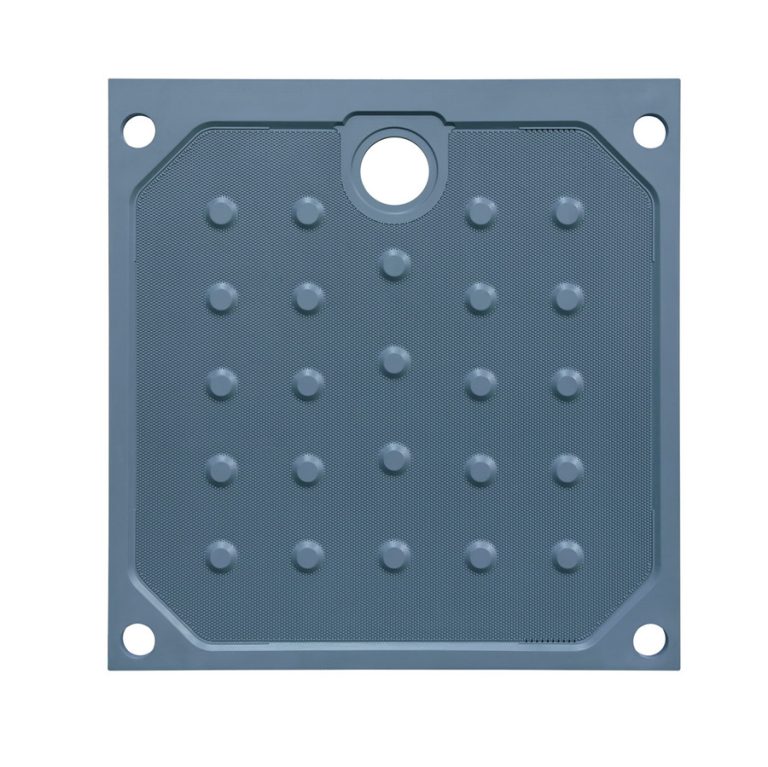

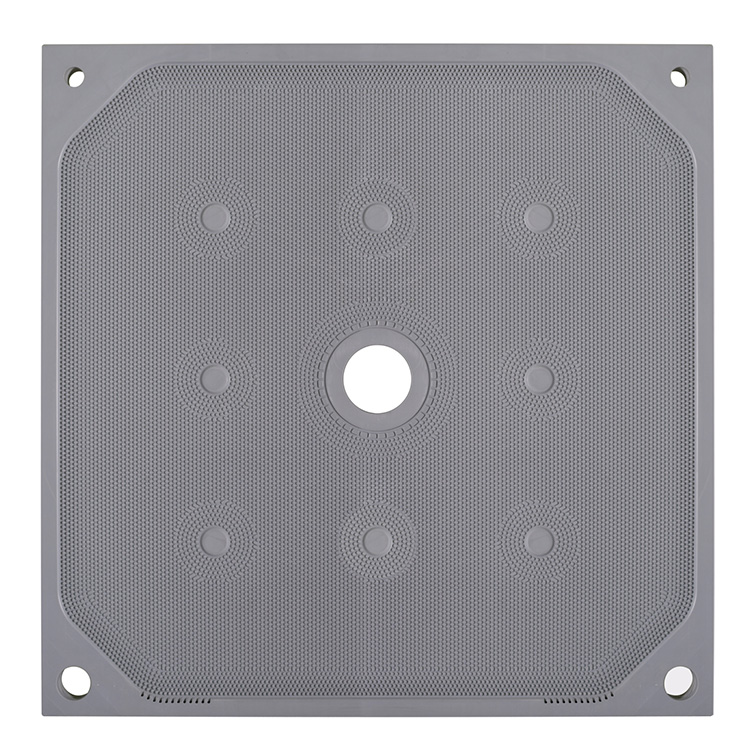

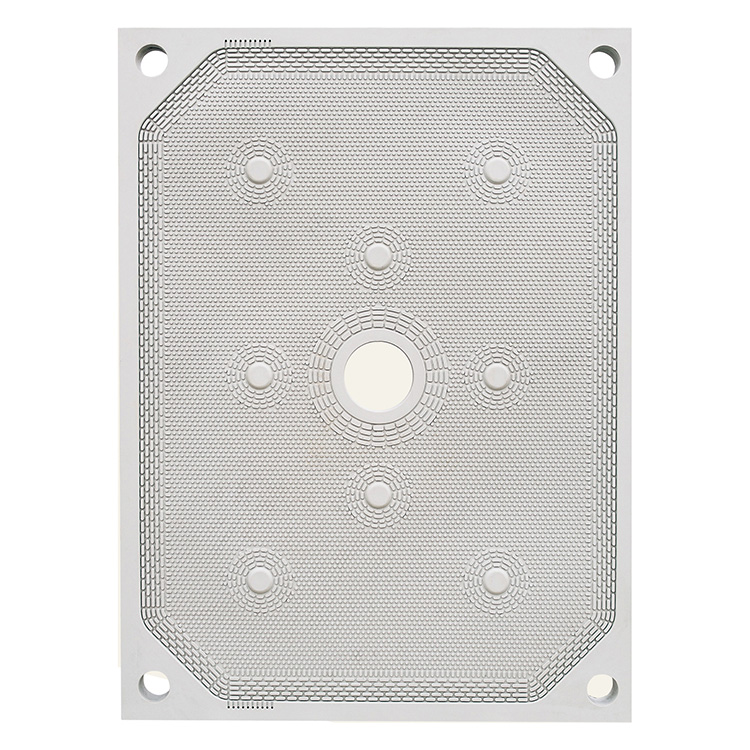

The filter plate is the core component of the filter press. Different filter plate materials, forms and qualities will have different effects on the filtration performance of the entire machine. The distribution of its feed inlet, filter point (filtration channel) and outlet channel has different designs for different materials. The filter plates produced and processed by our company are made of imported TPE elastomer and high-strength polypropylene, so that the filter plates have the elasticity of rubber filter plates and the toughness and rigidity of polypropylene filter plates, making the filter plates better sealed.

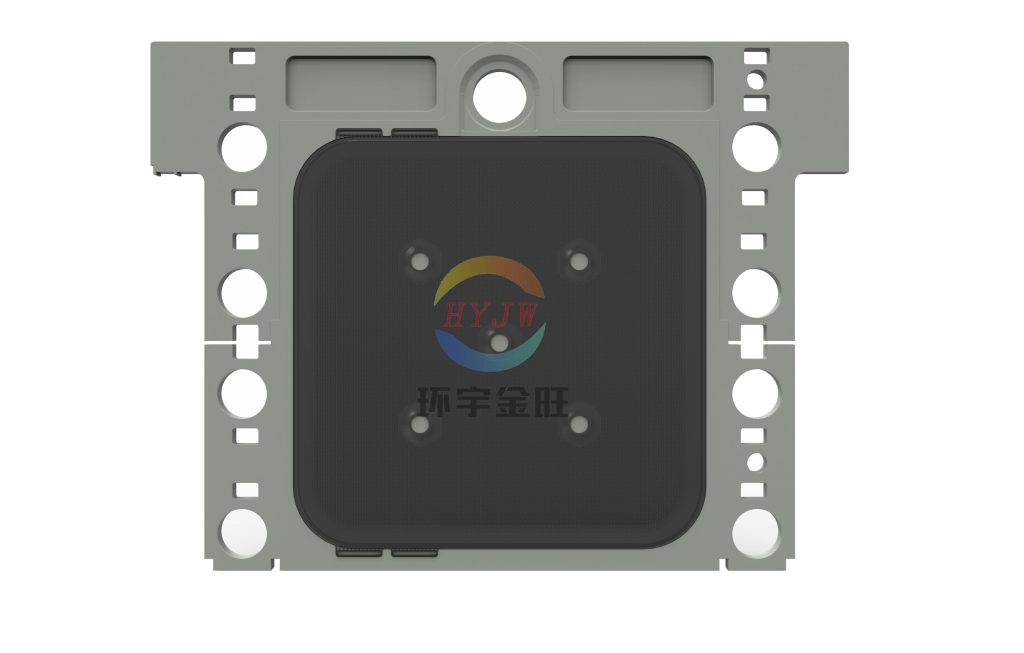

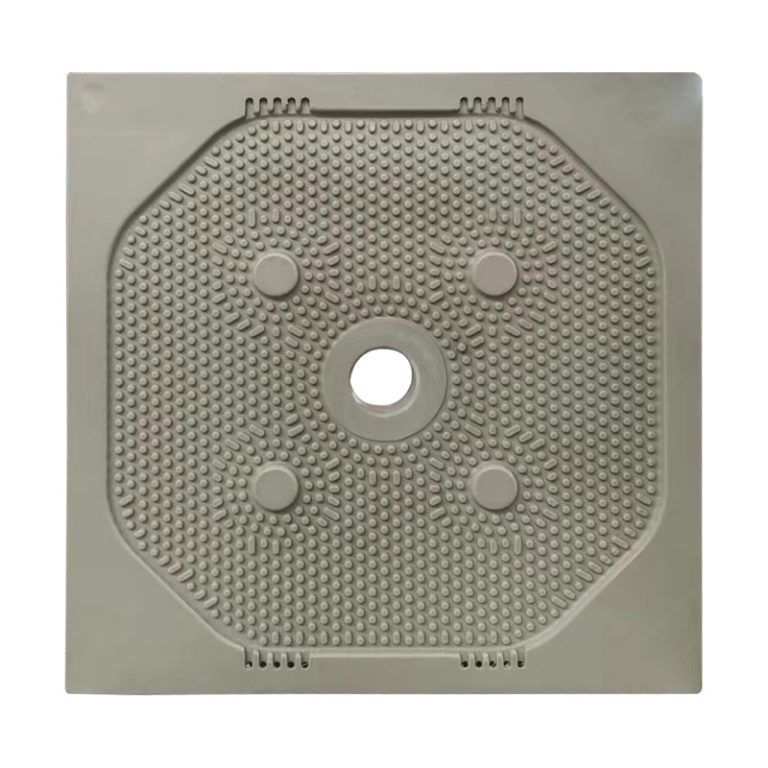

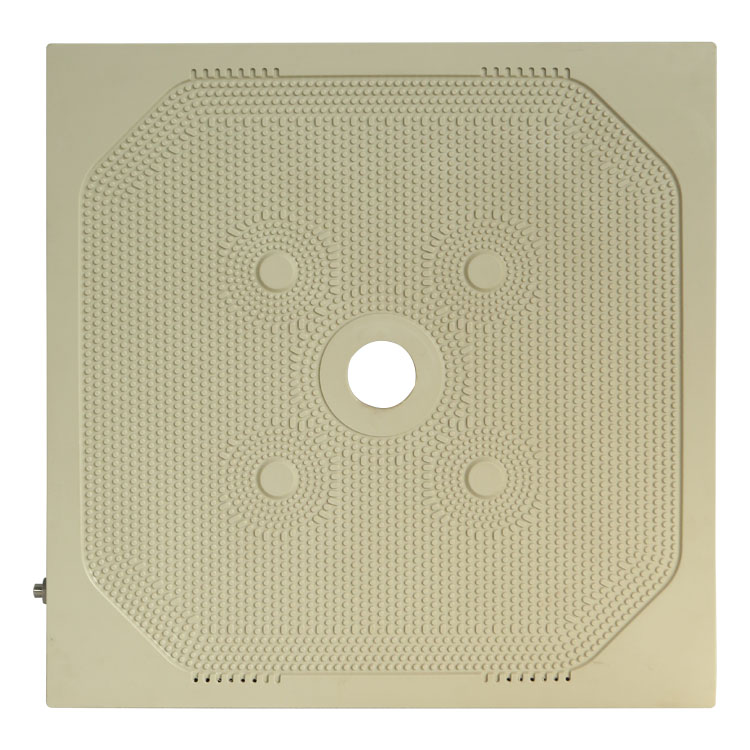

Jinwang Filter Plate

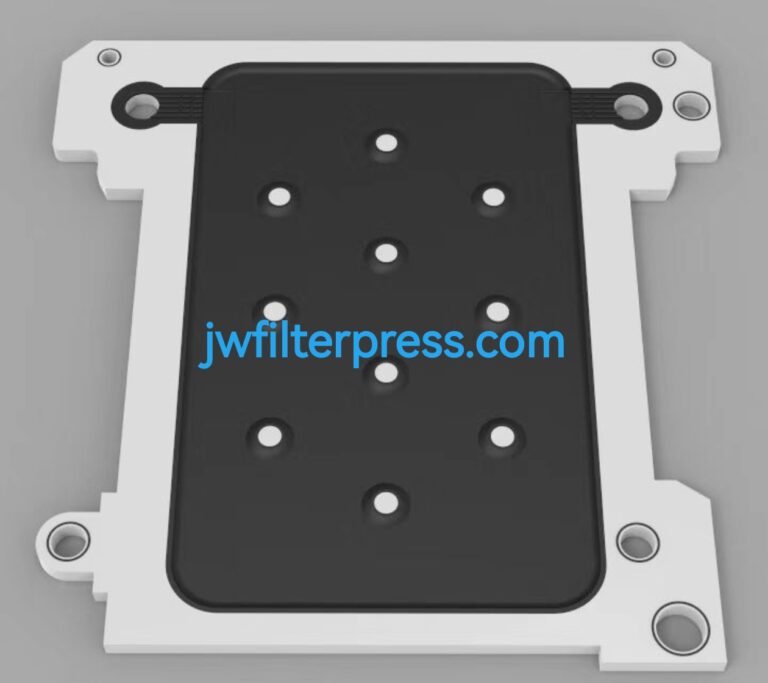

JINWANG filter plate, excellent quality, exquisite workmanship, can be perfectly matched with major well-known brands of filter presses.

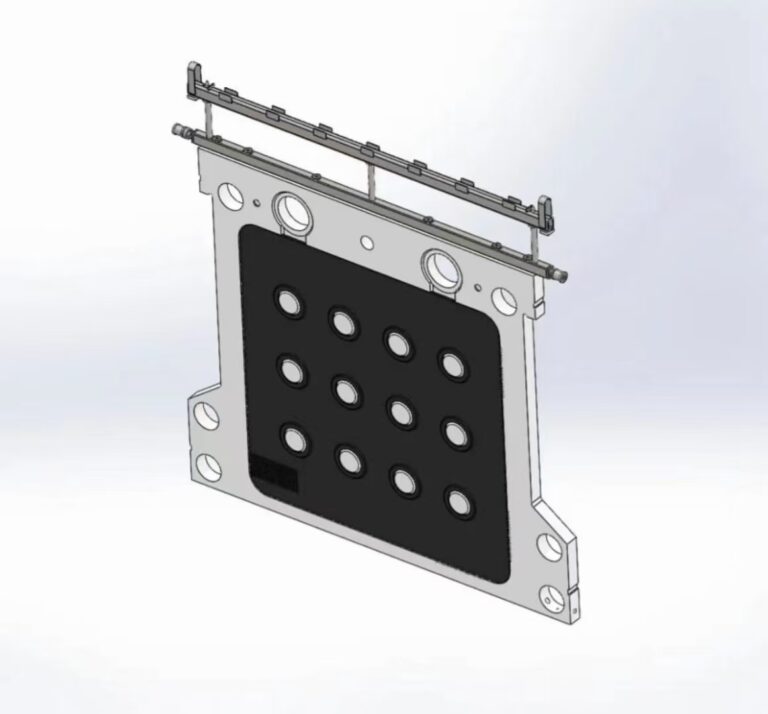

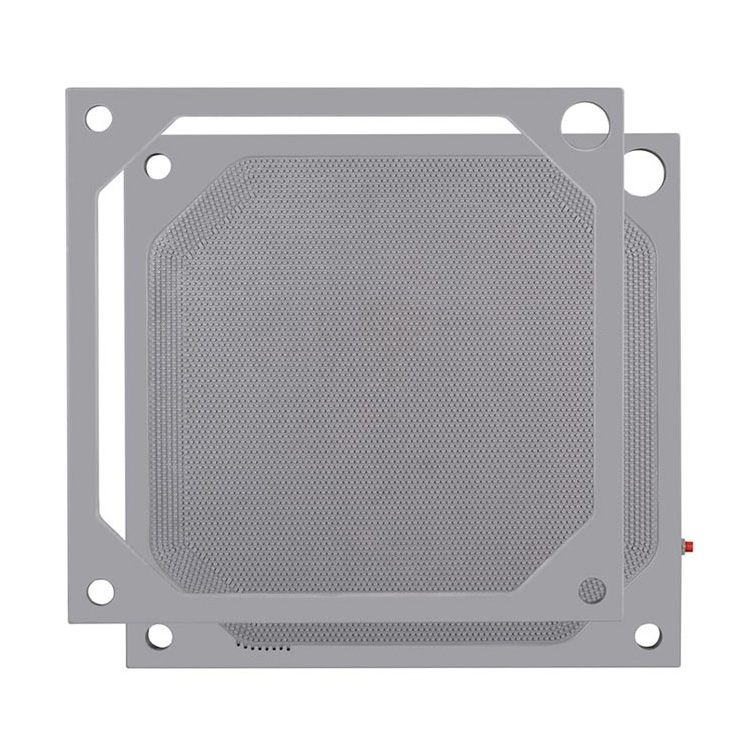

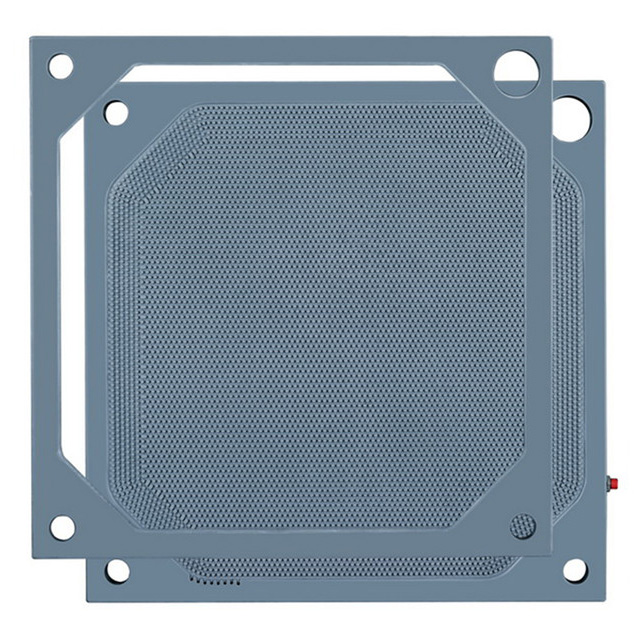

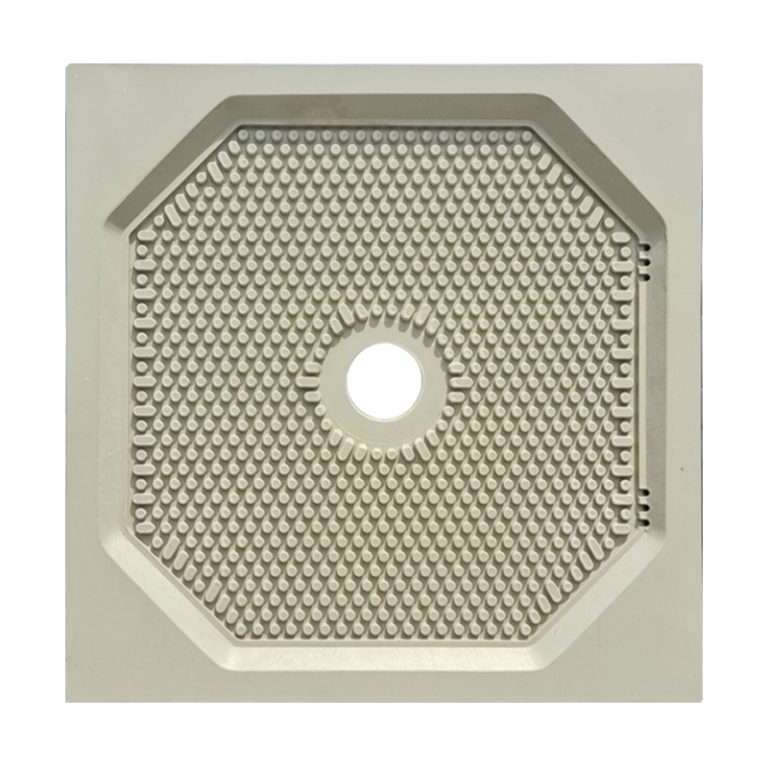

FFP3716

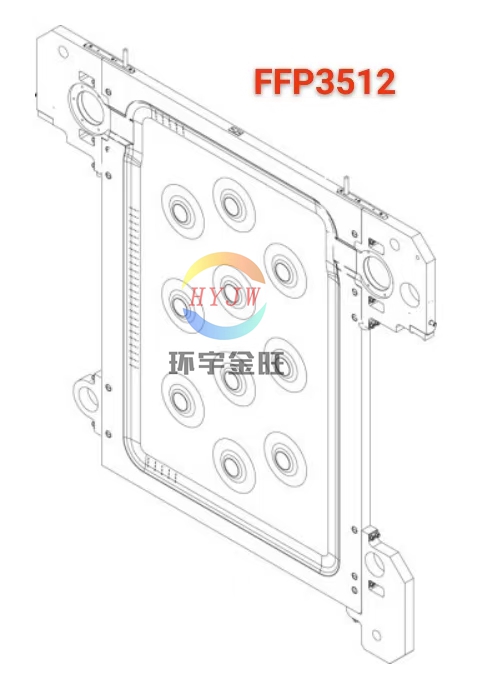

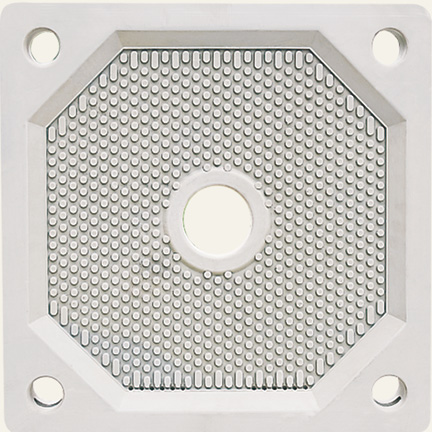

FFP3512

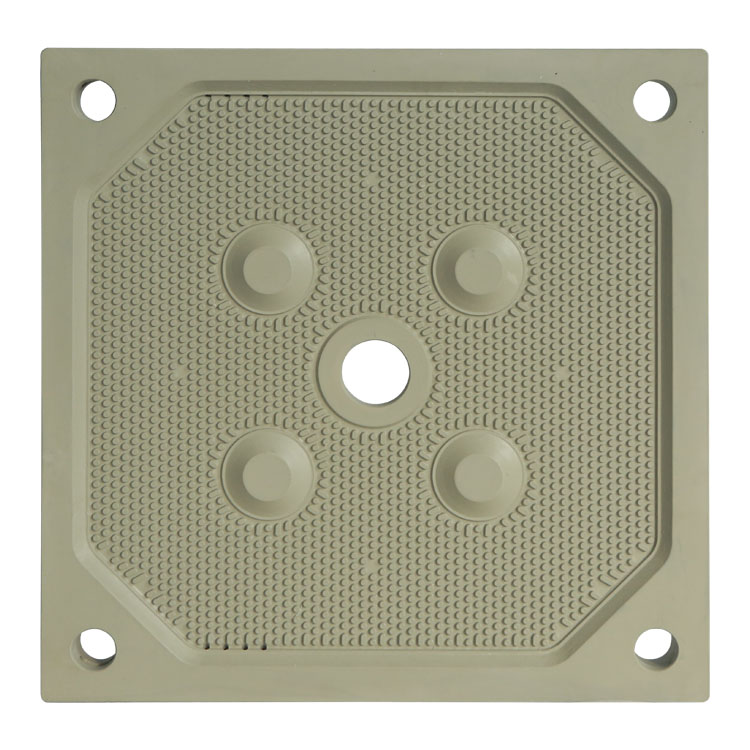

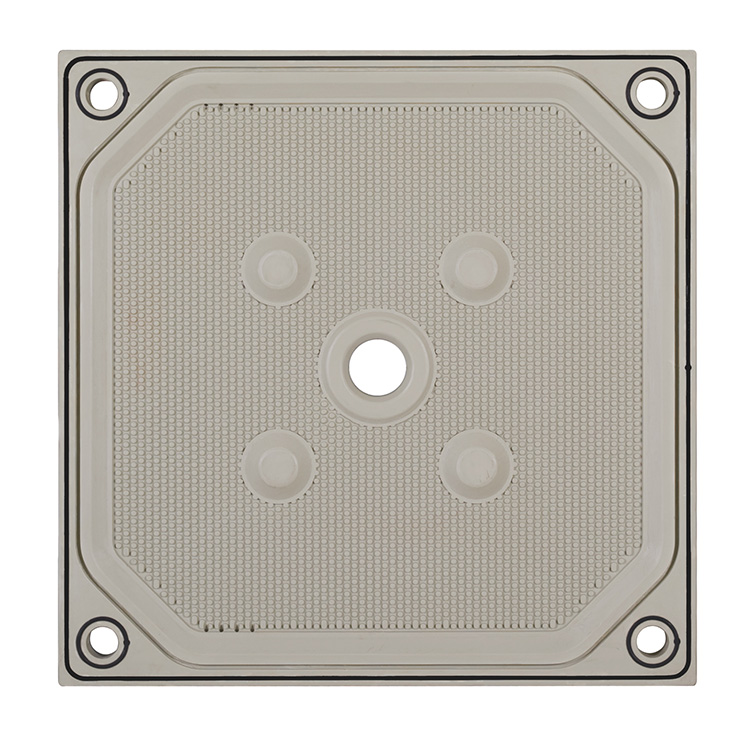

300 Rubber Filter Plate

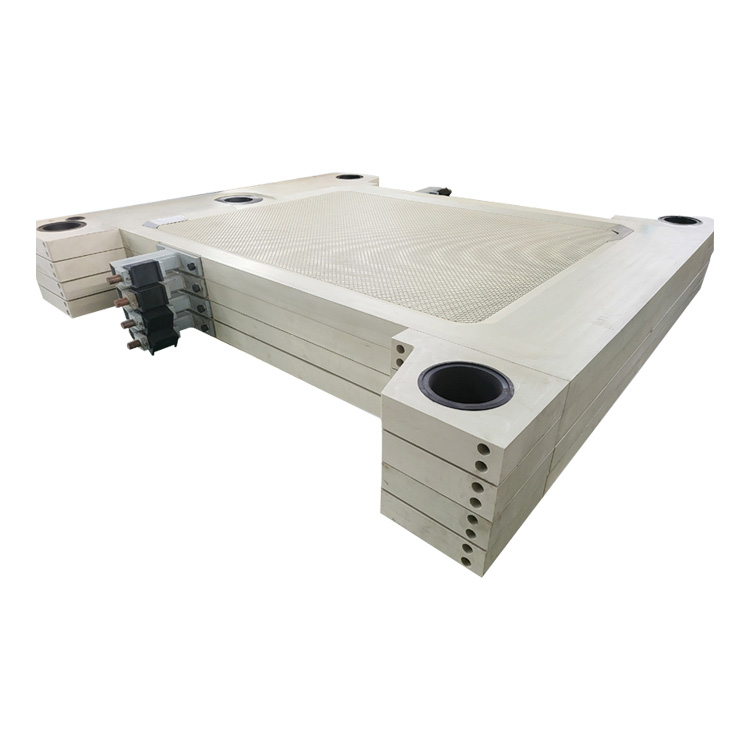

About Filter Presses

The filter plate is the main element of a filter press. The material, shape and quality of the filter plate affect the overall filtration efficiency in different ways. Our filter plates are made from imported TPE elastomers and high strength polypropylene, giving them the elasticity of a rubber plate and the strength and rigidity of a polypropylene plate, as well as a better compression seal.

Equipment Advantages

High power

High pressure high

Easy to replace

Long service life

Suitable for solid-liquid phase separation process in coal, metallurgy, mining, petroleum, chemical industry, printing and dyeing, medical treatment, foodstuff, waste water treatment and other industries.

Advantages Of Single-Chamber Feed Air Flow Through Water-Washed Filter Cake Filter Press:

1. Compared with the same type of filter plate, the filtering area is increased15%.

2.Good sealing effect.

3. The filter cloth is easy and safe to replace.

4. There are no dead ends or short circuits during blowing and washing, which can reduce Moisture content.

5. Save 30%-50% of washing water.

6. Clean the backflush pipe and feed pipe without residue and backflush Valve life is more than doubled.

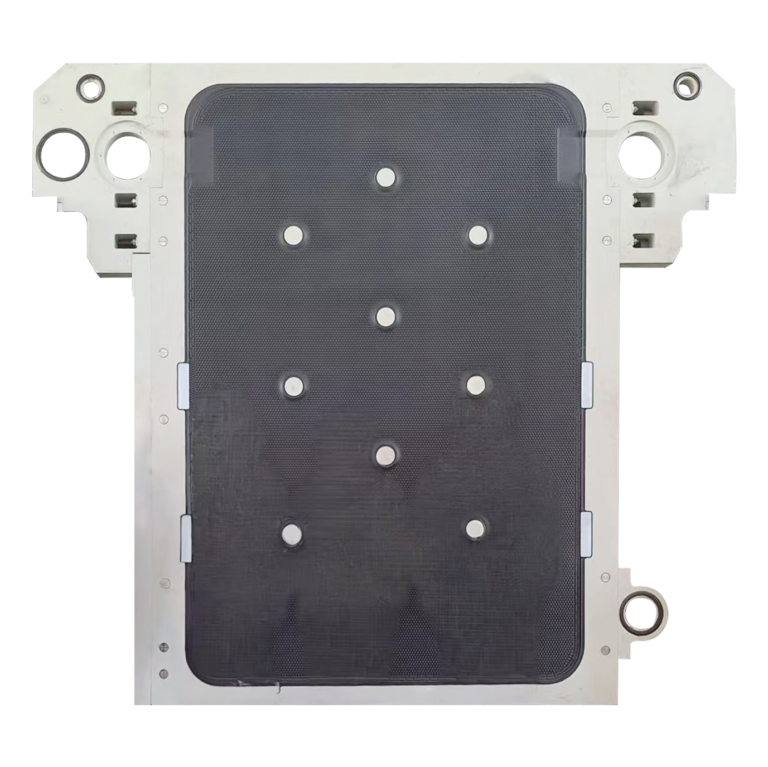

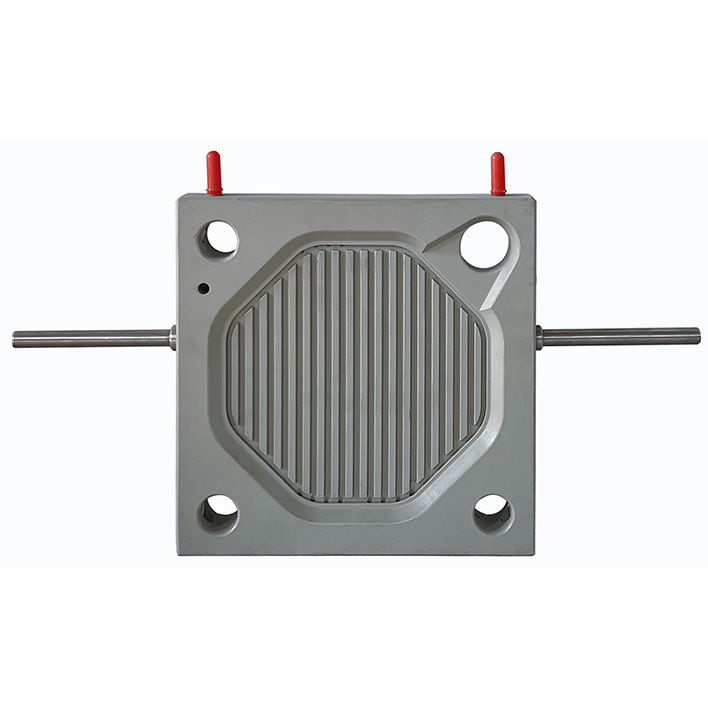

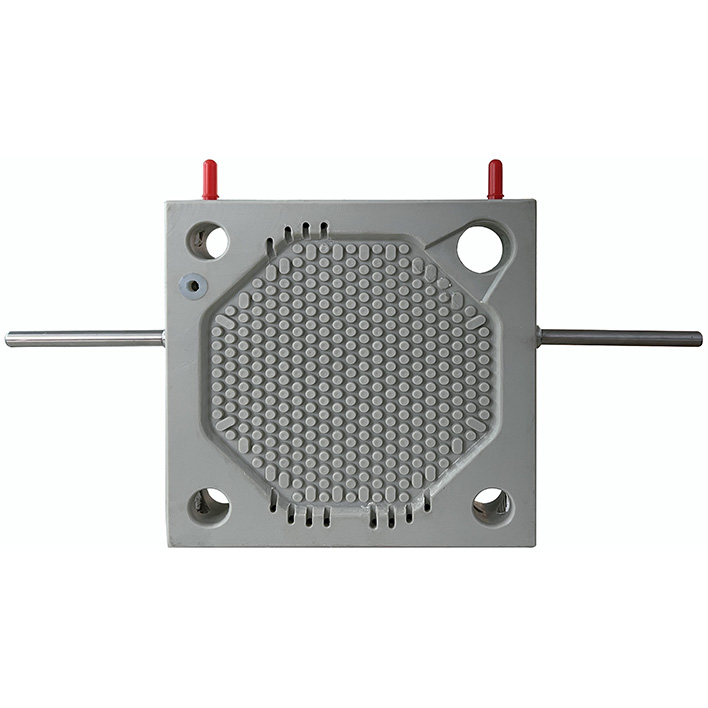

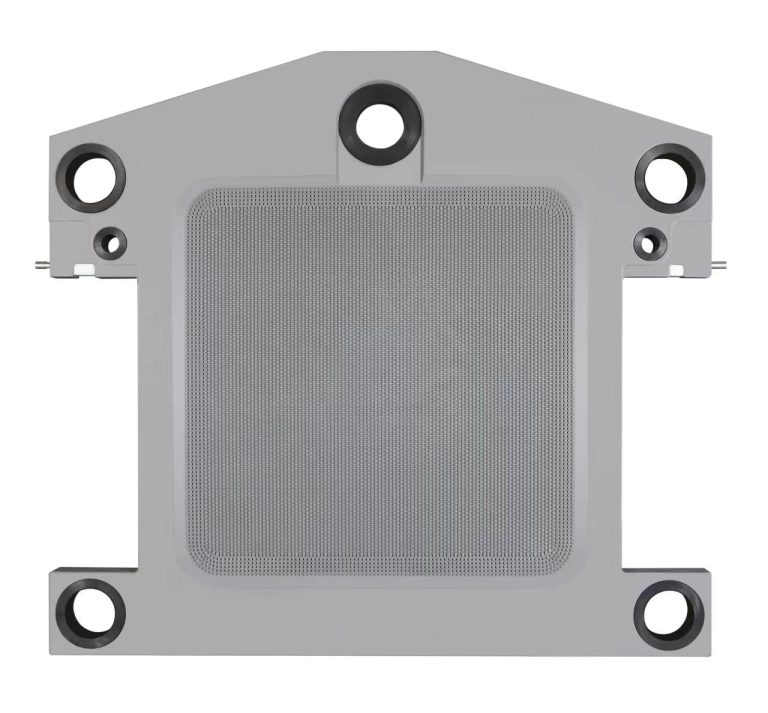

Plate and frame filter plate

Plate and frame filter plates are usually made of metal or plastic materials. It has a sturdy structure that can withstand heavy pressure. The internal space of the plate and frame is divided into several small chambers by the filter plate, which are used for filtration operations in the solid-liquid separation process.

Both sides of the filter chamber are closed by adjacent filter plates and equipped with drainage devices for draining the filtrate. The filter chamber is formed by pipes or slotted plates located on either side of a frame within which the filter cake is formed.

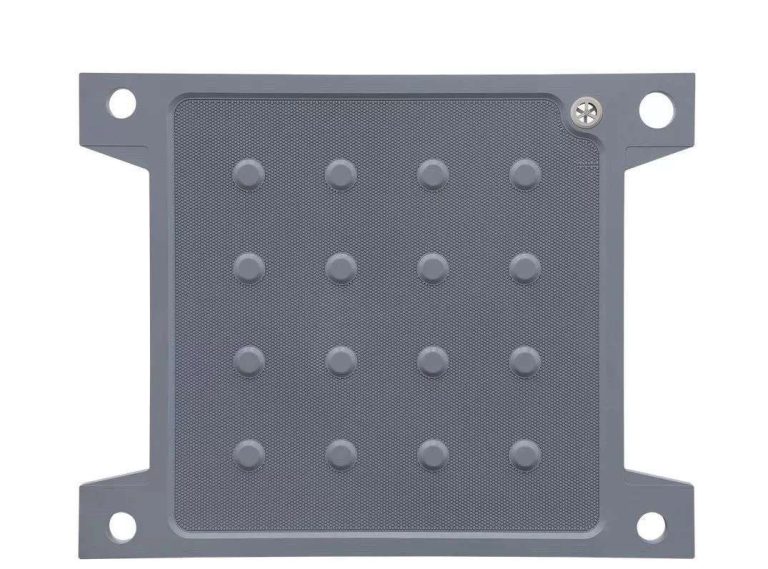

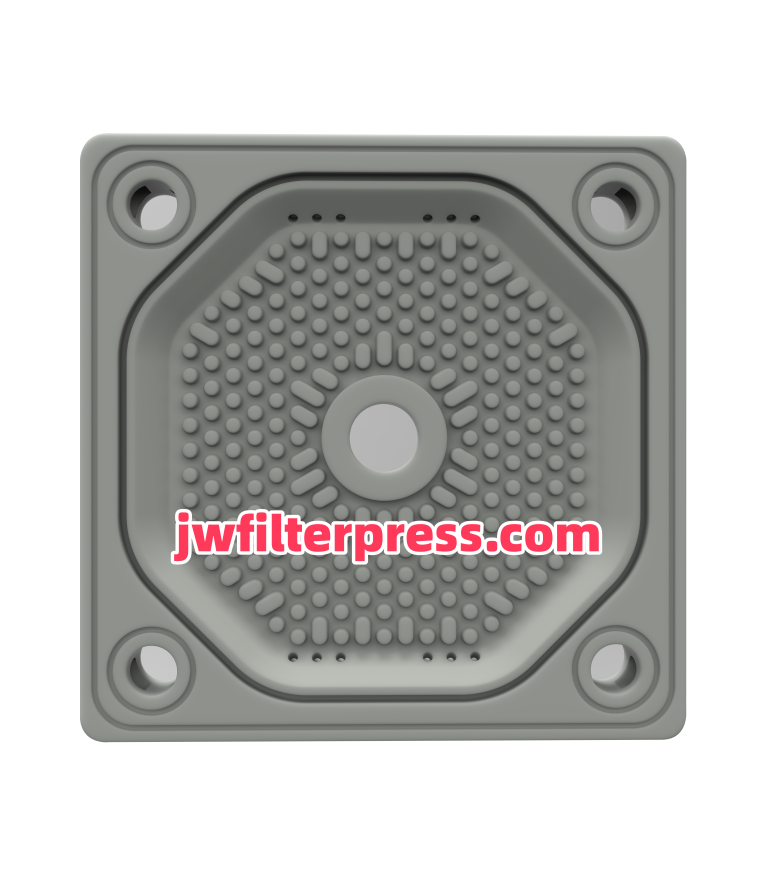

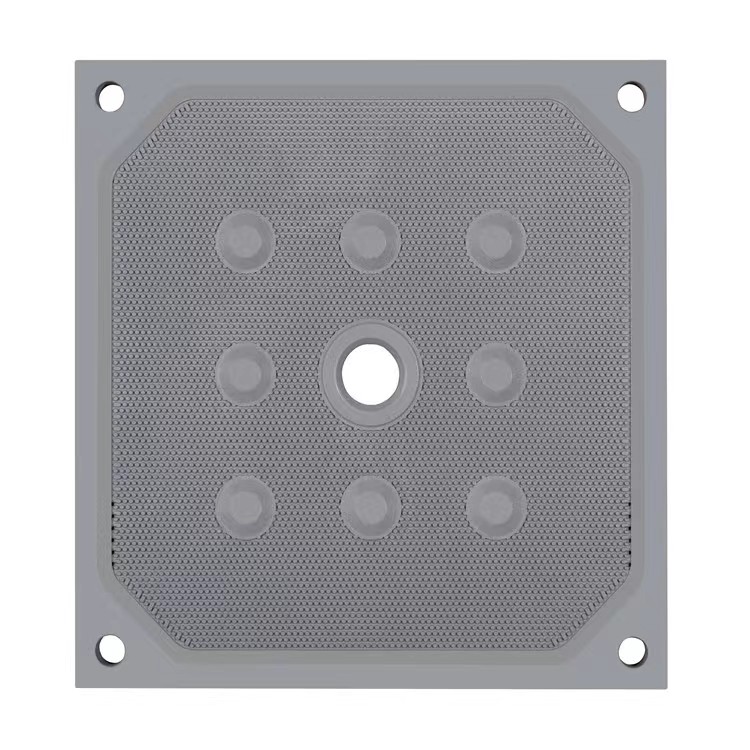

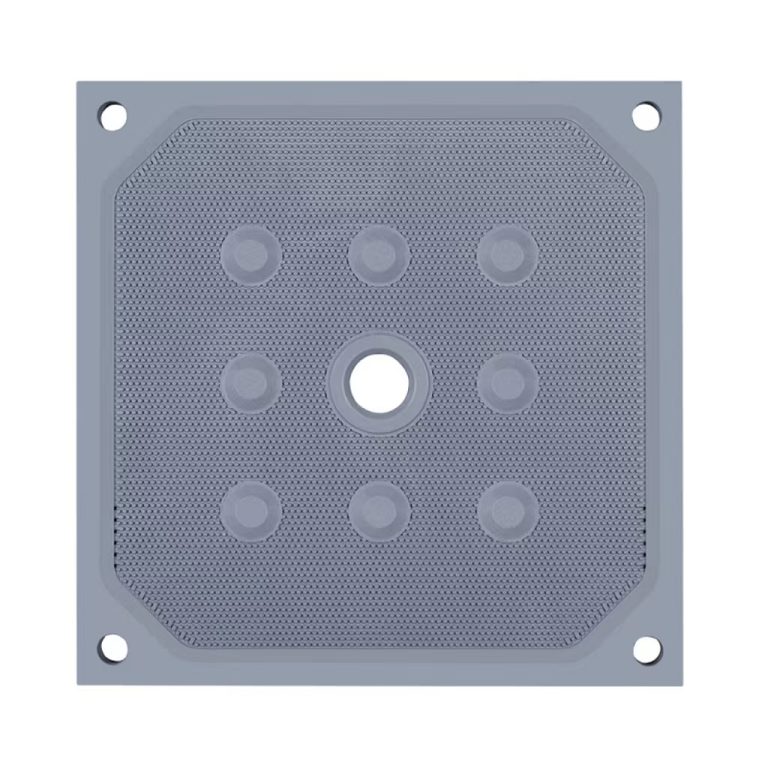

Chamber filter plate

The chamber filter plate is a solid filter plate. Two adjacent recessed filter plates are placed to form a filter chamber. The filter plate is recessed on both sides. Every two filter plates are combined to form a box-type filter chamber. There are grooves on the surface of the filter plate. Filter cloth is fixed to each filter plate. Its main advantages are less loss during feeding, fast filtration speed, high temperature and high pressure resistance, good sealing performance, uniform filter cake washing, and low moisture content. , each filter chamber has high pressure and is not easy to damage the filter plate.

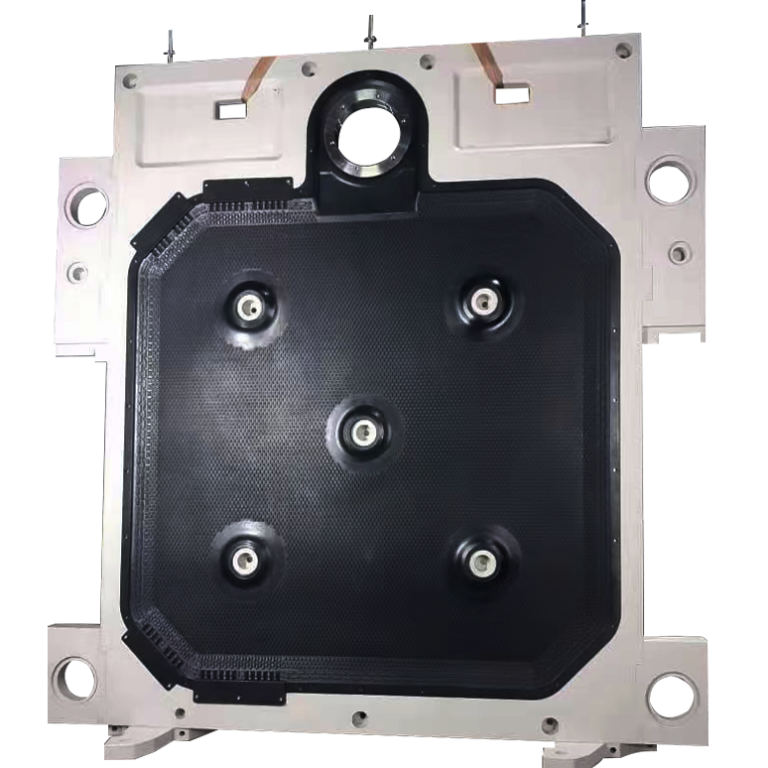

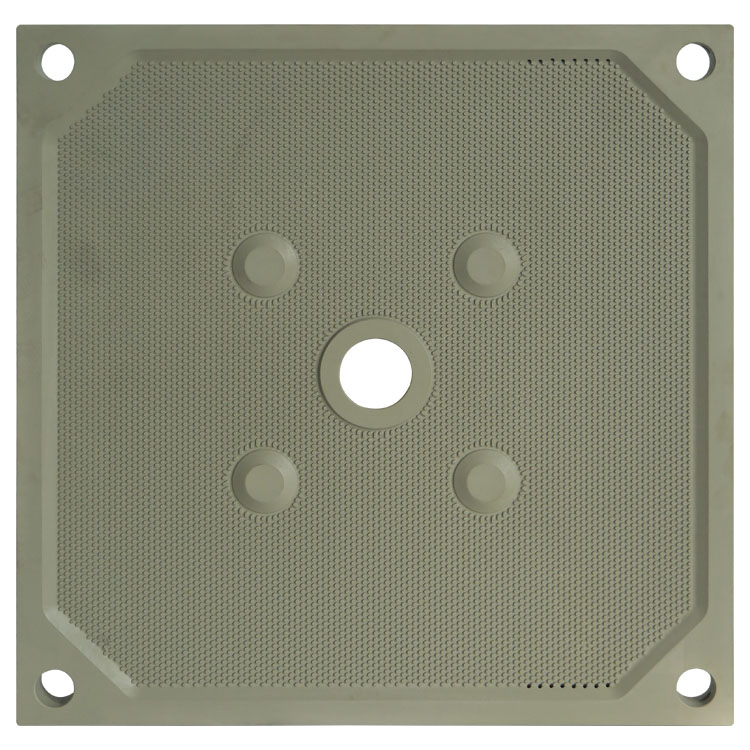

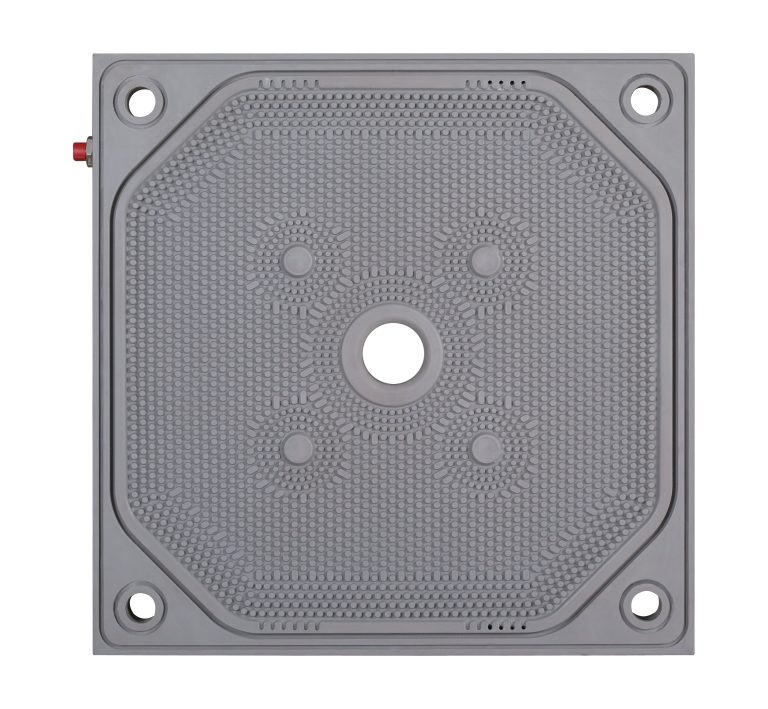

Membrane filter plate

The filter plate of the membrane filter press is a combination of a membrane filter plate and a chamber filter plate. The chamber filter plate has a solid structure, while the diaphragm filter plate consists of a diaphragm and a core plate to form an inner chamber structure.

The membrane filter plate consists of two membrane sheets and a core plate. When external media (water or compressed air, etc.) enters the chamber between the core plate and the diaphragm, the diaphragm bulges, thereby compressing the filter cavity composed of the diaphragm filter plate and the chamber filter plate to achieve better separation effects. , reduce the moisture content of solids. The diaphragm is the main component, and repeated movement can easily cause deformation and damage to the diaphragm.

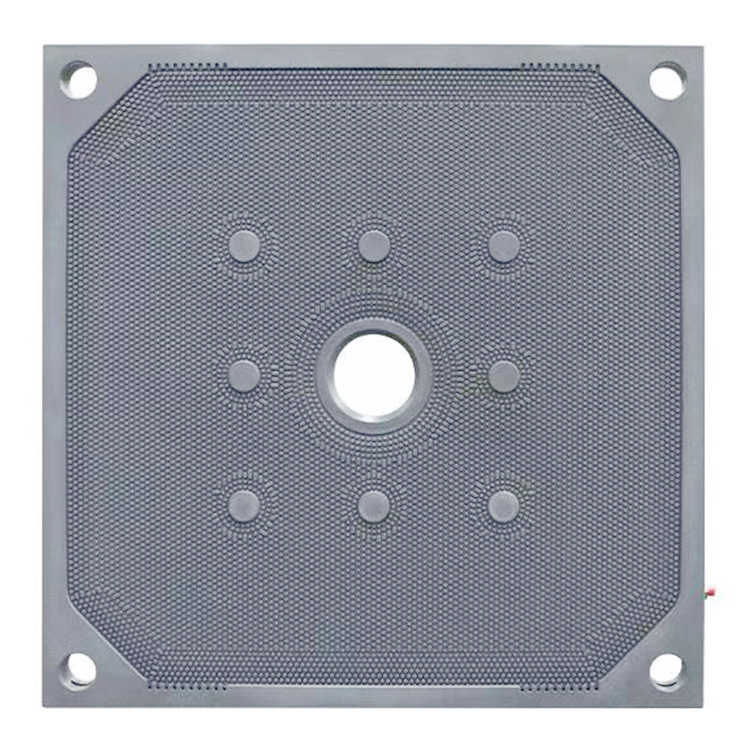

VPA1540 filter plate

Filter plate is the core element of filter press.The material, form and quality of the filter plate will have different effects on the overall filtration performance.The filter plate made by our company is made of imported TPE elastomer and high-strength polypropylene, which makes the filter plate have both the elasticity of rubber filter plate and the toughness and rigidity of polypropylene filter plate, and the filter plate has better sealing when pressed.

Cast iron filter plate

Cast iron filter plate is a commonly used type of filter plate in industrial filtration equipment, which is mainly used for solid-liquid separation process in filter presses and other equipment. Cast iron filter plates are usually made of high-strength cast iron material, which has a certain degree of wear resistance and corrosion resistance.

The main features of cast iron filter plate include:

- Wear-resistant: cast iron material has high hardness and wear-resistant, which can withstand pressure and friction under high pressure and work stably for a long time.

- Corrosion resistance: cast iron filter plate has a certain degree of corrosion resistance, can cope with some corrosive media filtration requirements.

- Stable structure: cast iron filter plate has a flat surface, stable structure and is not easy to be deformed, which ensures the efficiency and stability of the filtration equipment.

- High-temperature performance: cast iron material has a certain high-temperature resistance, suitable for some high-temperature filtration operations.

Cast iron filter plate is mainly used in chemical industry, metallurgy, mining and other fields of solid-liquid separation process, used to filter a variety of solid particles containing liquid or suspension. Cast iron filter plate is suitable for various occasions with high filtration requirements and high working pressure, such as solid-liquid separation, dehydration, solid phase concentration and other processes.

In the actual selection of cast iron filter plate, you need to take into account the specific filtration requirements, working environment and equipment design and other factors to ensure that the selection of the appropriate cast iron filter plate models and specifications to achieve the desired filtration effect.