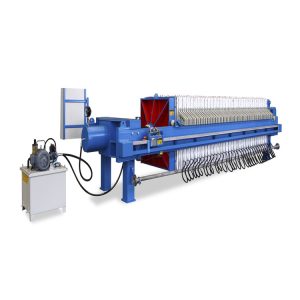

Model 1500 fully automatic filter press with filter cloth cleaning system

Automatic filter presses are widely used in production. The top of each filter plate of this filter press is covered with water outlets. There is a free space for the filtrate between the membrane and the surface of the plate. Install a waterproof membrane between the board and frame. The plate and frame are pulled together between two support plates and form the chamber in which the filtrate separation takes place. Long sheets of material serve as filter baffles, passed between the plates and stretched using hydraulics.

When assembling the package, existing holes in the filter plate are combined and formed into through-channels. Filtrate is supplied through them, followed by liquid for cleaning and air for blowing. There are also channels for draining filtrate, liquid and air. After the filtrate is separated, washed and dried, pressurized water is passed into the space between the membrane and the filter plate to squeeze out the sediment. The filter plate is then removed and the filter cake is removed from the filter cloth. Unload the filter cake onto a running conveyor belt.

The main advantages of this type of filter press are: process automation, compactness and fast discharge times.