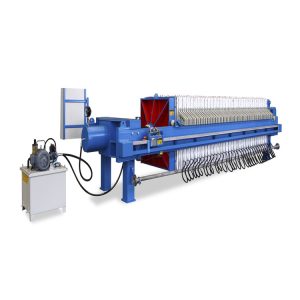

Type 800 low-position high-efficiency water-washing filter press

1. Product introduction

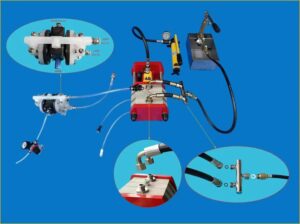

The low-side walking water washing device is a key part of the fully automatic filter press. It transmits signals to the centralized control room through the 5G system. Staff can monitor equipment operation from the centralized control room, saving labor and increasing customer selectivity.

2.Features and advantages of this model

1. The motor adopts Guomao, Delta and Kaiyuan brands, with balanced and reliable operation and low power consumption;

2. Use products from the three major brands of Omron, Siemens and Schneider to achieve automatic control of the entire process;

3. Hydraulic system: Hydraulic components are all made of high-quality products; integrated blocks are processed by machining centers; fuel tanks are produced using advanced manufacturing technology

4. The main beam is made of H-shaped steel, which has strong impact resistance and side bending resistance, completely solving the bending problem of the main beam.

5.Diaphragm pressing, maximum 25KG, the moisture content of filter cake after pressing will be reduced to less than 20%;

Scope of application: Suitable for coal washing, metallurgy, mining, petroleum, chemical industry, dyes, medicine, food, sewage treatment and other industries.

三、 Maintenance of filter press

Maintenance of the filter press during use is very important. To do this you should do the following:

1) Check carefully at any time whether the connection is firm and whether the parts are in good condition. If abnormal conditions are found, maintenance personnel must be notified in time for repairs.

2) Regularly check bearings, piston rods and other components to keep them clean and ensure flexible movement.

3) Regularly conduct insulation and reliability tests on the electrical control system. If any inflexible movement caused by electrical components is found, they should be repaired or replaced in time.

4) Maintenance of the hydraulic system is mainly to check and maintain the sealing of hydraulic components and interfaces.

5) Frequently check the sealing surface of the filter plate to ensure it is smooth and clean; before pressing, carefully check the filter cloth to ensure that there is no folding, damage, or slag inclusion, and make it flat and intact to ensure the filtration effect. At the same time, the filter cloth must be cleaned frequently to ensure the filtration performance of the filter cloth.

6) If not used for a long time, the filter plates should be cleaned, arranged neatly on the filter press frame, and pressed with 1-5MPA pressure. After cleaning, the filter cloth should be dried and the exposed parts of the filter cloth should be cleaned. The piston should be greased.

7) Use HM46 or HM68 hydraulic oil and keep it clean. After the new machine is put into operation for the first time, the hydraulic oil must be replaced once a week. When changing the oil, the used hydraulic oil in the fuel tank and cylinder must be drained. After one month of continuous use, the hydraulic oil must be replaced. It is recommended to replace it every three months in the future to ensure the normal use of the filter press.